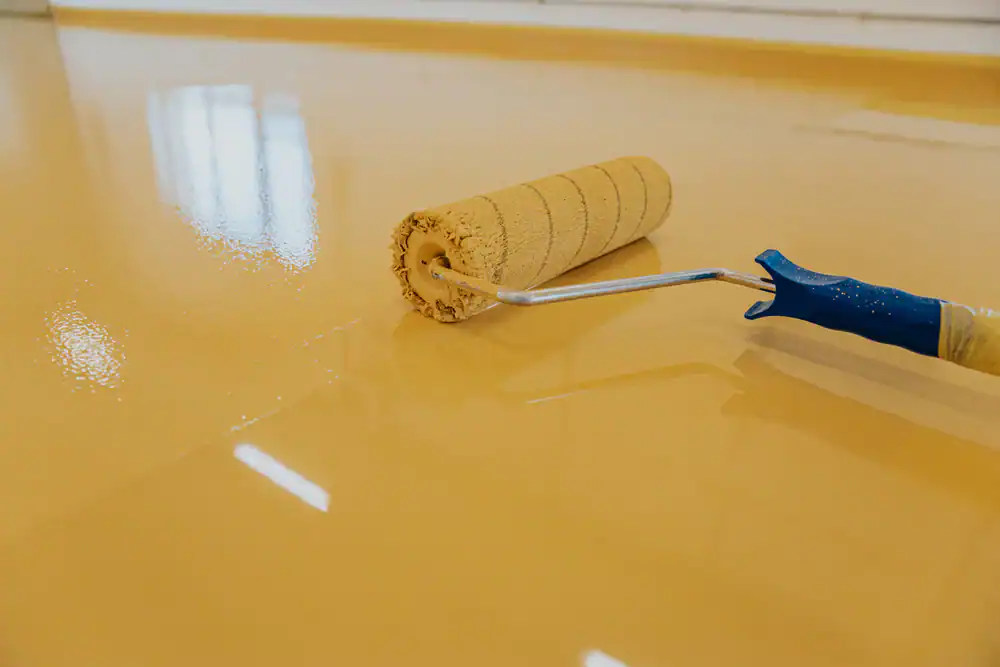

Your pharmaceutical flooring system includes comprehensive surface preparation, specialized primers, and multiple coating layers designed for your specific environment. We evaluate chemical exposure patterns, traffic loads, and cleaning protocols to recommend the optimal system configuration.

Static-dissipative options protect sensitive equipment and prevent dangerous electrostatic discharge around volatile compounds. Chemical-resistant formulations withstand acids, solvents, and cleaning agents without degrading. Antimicrobial additives provide additional protection against bacterial growth.

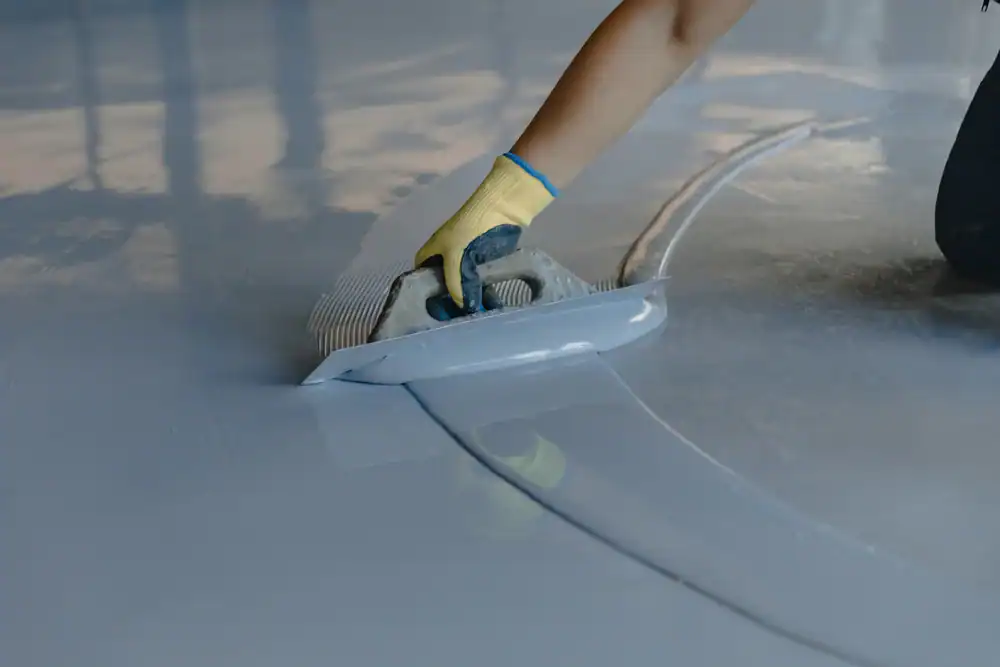

Each installation includes proper coving where floors meet walls, eliminating 90-degree corners where contaminants typically accumulate. The result is a completely sealed environment that supports your contamination control strategy while meeting regulatory requirements.